DFM fuel flow meter is engineered for accurate measurement of fuel consumption in fuel lines and monitoring engine operating time in both vehicles and stationary machinery.

Measured liquids:

- diesel fuel,

- heating oil,

- pther liquid fuels and mineral oils with a kinematic viscosity range of 1.5 to 6 mm²/s.

Scope of application

Accurate fuel usage monitoring with DFM fuel flow meters

DFM is a versatile device that provides direct fuel consumption measurement and can seamlessly integrate with vehicle telematics and GPS tracking systems, or function as a stand-alone solution for fuel monitoring.

The fuel flow meters help monitor fuel usage, optimize fuel efficiency, and reduce operational costs by ensuring that engines operate within their most efficient fuel consumption range.

Additionally, DFM fuel flow meters can track engine operating time in various working modes, allowing for better maintenance scheduling and overall management of fuel resources.

Incorporating DFM fuel flow meters into a fleet management or vehicle telematics system enhances data accuracy, enabling more informed decision-making, improved operational efficiency, and better fuel management practices.

Types of DFM fuel flow meters

DFM flow meters are available in various configurations to meet diverse operational needs and engine specifications:

A) by measuring principle:

-

- single-chamber,

- two-chamber (differential).

B) by output interface

- wired: CAN bus, RS (Modbus), pulse,

- wireless: Bluetooth,

- autonomous: display-only counter.

These fuel flow meters can be installed in fuel lines using several standard installation schemes. For detailed instructions, please refer to the installation guides.

Single chamber DFM fuel flow meters

| Connecting thread | M14x1.5, M16x1.5 |

| Nominal pressure, bar | 2 |

| MAX pressure, bar | 25 |

| Supply voltage, V | 10-45 |

| Overvoltage protection, V | ≤100 |

| Current consumption, mA (24 V/12 V), mA | 25 / 50 |

| Ingress Protection Rating | IP54 |

| Relative accuracy error per chamber, %, not more than | 1 |

| Operating temperature, (without/with display), °C | -40..+85 / -20..+60 |

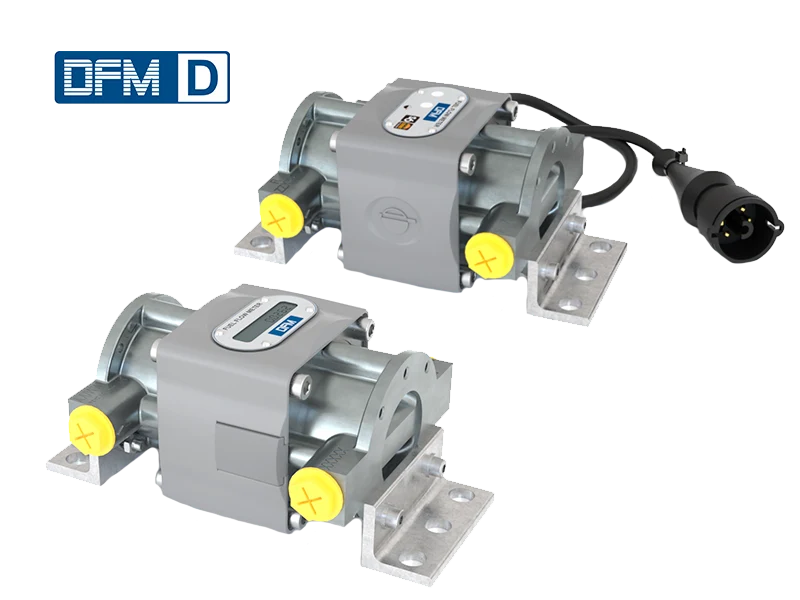

Differential DFM fuel flow meters

| Connecting thread | M14x1.5 |

| Nominal pressure, bar | 2 |

| MAX pressure, bar | 25 |

| Supply voltage, V | 10-45 |

| Overvoltage protection, V | ≤100 |

| Current consumption, mA (24 V/12 V), mA | 25 / 50 |

| Ingress Protection Rating | IP54 |

| Relative accuracy error per chamber, %, not more than | 1 |

| Operating temperature, (without/with display), °C | -40..+85 / -20..+60 |

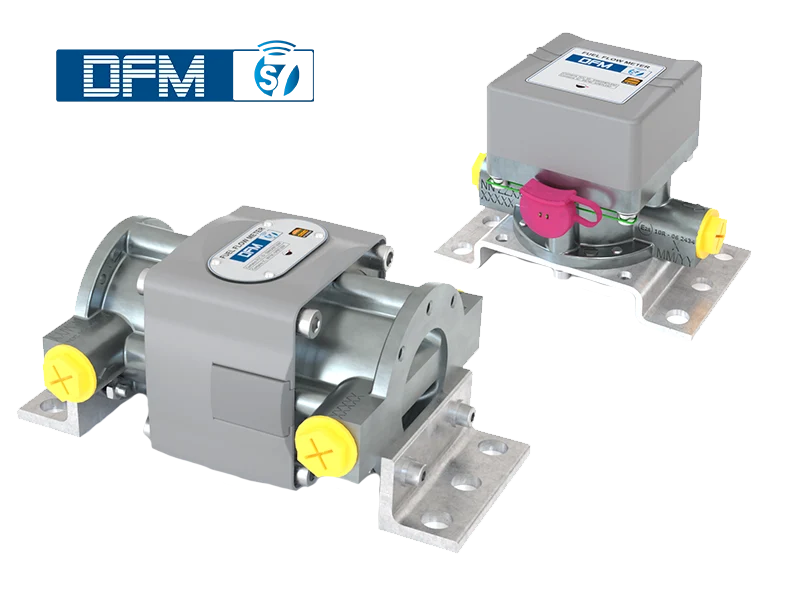

Wireless DFM fuel flow meters

| Max pressure, bar | 25 |

| Interface | Bluetooth 4.X |

| Tx power, dBm | +4 |

| Maximum distance between fuel flowmeter and receiving device, m | 50 (when installed in line-of-sight) |

| Battery life, years | not less than 5 |

| Operating temperature | ºС -40…+85 |

| Ingress protection rating (IP Сode) | IP54 |

DFM Marine – flow meters for heavy machinery

| Maximum pressure: flange connection / thread connection | 25 atm / 16 atm |

| Maximum temperature of working fluid | 95°С / 150°С* |

| Fluid viscosity | 1,5 – 6,0 mm2/s (cSt) |

| Measurement chamber material | brass |

| Body/connection materials | brass/duralumin** |

| Communications standard | CAN J1939/S6 + NMEA2000 digital interface RS232/485 |

| * — under the order | |

| ** — specified in the order |

Industrial DFM flow meter

| MAX flow rate | 25 м3/h |

| MAX pressure | 1.6 / 6.4* MPa |

| Interface | – CAN(J1939)/S6 interface / pulse output / autonomous (without interface) |

| Kinematic viscosity of liquid | 0.55-300 mm2/s (cSt) |

| Ambient operation temperature | from -20 to +60 °С |

| Operating principle | oval gears rotation |

| Connection to pipeline | flange, thread |

| Battery lifetime | up to 36 months |

| * - on request |

Data provided by DFM fuel flow meters

Fuel consumption

- Instant fuel consumption, L/H

- Hourly fuel consumption in “Forward” line

- Hourly fuel consumption in “Return” line

- Total fuel consumption, L

- Total fuel consumption in “Idling” mode of engine operation

- Total fuel consumption in “Optimal” mode of engine operation

- Total fuel consumption in “Overload” mode of engine operation

- Total fuel consumption in “Negative” mode of flow meter operation (return exceeds supply)

Engine operating time

- Total operating time, h

- Total operating time in “Idling” engine operation mode

- Total operating time in “Optimal” engine operation mode

- Total operating time in “Overload” engine operation mode

- Total operating time in “Negative” flow meter operation mode

- Total operating time of Supply chamber

- Total operating time of Return chamber

- Operating time of Supply and Return chambers in each mode of engine operation

Special

- Engine operating time in “Tampering” mode, h

- Engine operating time in “Interference” mode, h

- Current engine operation mode as per fuel consumption rate

- Fuel temperature

- Temperature correction status

- Correction coefficient value

- Battery charge

Selecting DFM fuel flow meter

To select a proper model of DFM fuel flow meter, it’s recommended to know the following parameters of an engine or fuel pump:

- fuel type used by the machinery,

- fuel line type (commonrail, pump-injector, etc.),

- hourly consumption in idling and maximum load,

- instant flow rate in idling and maximum load (for each fuel line),

- what telematics device (or display unit) is installed on the machinery.